Cold stabilization module for Molson Coors’ new premium lager

Molson Coors, the world’s seventh largest brewery, has been brewing quality beers since 1774. To expand its range with a premium, non-pasteurized lager, the brewery was looking for a partner with proven expertise in the field of cold stabilisation. Agidens took up the challenge and implemented in five months’ time a Cold Stabilisation Module (CSM) on the Molson Coors brewery site in Zagreb, Croatia.

COLD STABILIZATION: NOTHING BUT ADVANTAGES

Compared to traditional pasteurisation techniques, the advantages of cold stabilisation with membrane filtration are numerous. While the quality and stability of the beer is guaranteed, this microfiltration technique performs better than flash and tunnel pasteurisation in terms of shelf life, taste protection (no heat treatment), product losses and overall use of WAGES (water, air, CO², energy and steam). As a result, the operational costs for microfiltration are up to 40 percent lower.

For Agidens, the challenge at Molson Coors was mainly the limited accessibility of the location where the module had to be installed. The site was only accessible via a tiny elevator (1.80m x 1.80m x 1.00m), which meant that the CSM had to be custom-designed, disassembled and transported before it could be installed on site. In addition, Agidens had to consider a sharp implementation period of five months.

TAILOR-MADE SOLUTION

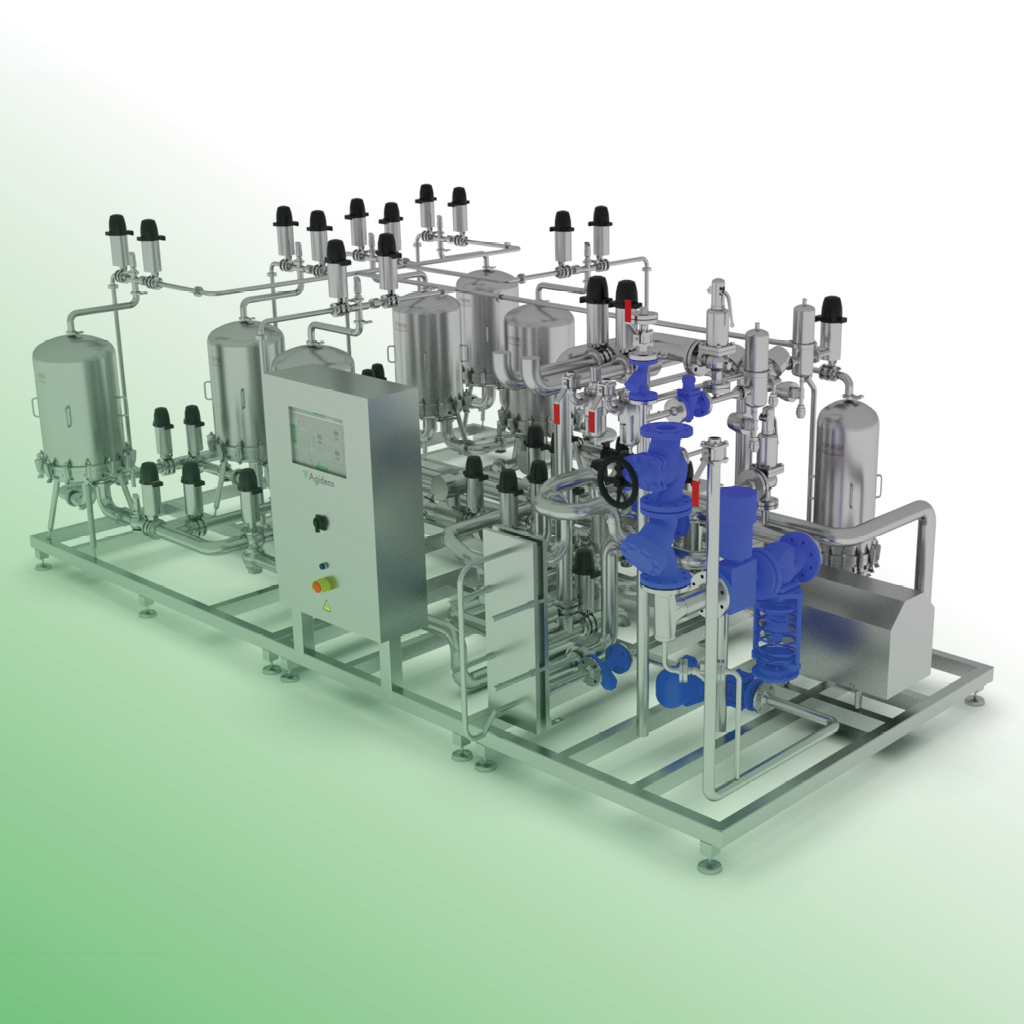

Agidens’ engineering team provided a tailor-made CSM solution that was integrated into the existing production line. The CSM installation consists of three modules: a filtration skid, a distribution cluster and a CIP skid – for a total length of 6.75 metres. The modules were assembled in the workshop, disassembled for transport and rebuilt on site. They filter an average of 250 hectolitres of beer per hour.

TECHNICAL INFORMATION

For the CSM modules, Agidens has opted for the flexible software platform Siemens TIA. This state-of-the-art platform lends itself perfectly to modular skid construction, such as the usage of the standard filter skids, simplifying maintenance and offering possibilities for expansion.

| Type | Product Pipe Size [DN] | Max. Product Flow [hl/hr] |

| CSM11-40 | 40 | 40 |

| CSM11-100 | 65 | 100 |

| CSM12-250 (Used at Molson Coors) |

65 | 250 |

| CSM12-300 | 80 | 300 |

| CSM24-600 | 100 | 600 |

A to Z integrated solution

A fluent integration in the plant while limiting production downtime is crucial in our approach. With our know-how in process design and automation experience in breweries all over the world, you can be assured of a fast and high-quality integration in your production plant.

Process know-how is what sets Agidens apart from other industrial service providers. Our filtration solutions have been developed based on more than 30 years of experience in the brewing industry. Regardless of your brewery’s specific design and software systems, Agidens delivers integrated systems that excel in flexibility and are fully compliant with the highest standards.